GAS FITTINGS

High Purity Gas Fittings

Comprehensive range of high-purity gas fittings designed to meet the stringent requirements of industries such as laboratories, pharmaceuticals, and semiconductor manufacturing. Constructed from high-grade stainless steel, these fittings are highly durable, corrosion-resistant, and engineered with precise threading and sealing mechanisms to prevent leaks and contamination, ensuring optimal performance in systems where gas purity is critical. Available in various sizes and configurations, they provide flexibility in design and application, supporting the safe and efficient delivery of gases.

Manufactured in adherence to international standards and certifications, AdvanceLab’s gas fittings guarantee reliability and safety. Their versatility makes them ideal for demanding environments where maintaining gas purity is paramount. Whether for laboratory use or high-tech manufacturing processes, these fittings uphold the integrity of gas systems and enhance overall performance. For more details, refer to AdvanceLab’s official catalog.

Features

Single-Stage Regulators

High pressure mediums enter through the inlet of the regulator to the high pressure chamber. When the hand wheel is turned clockwise, it compresses the spring and creates a force on the diaphragm, which pushes the regulator’s poppet open. This releases the gas into the low pressure chamber, exerting an opposing force on the diaphragm which then closes the passage. Equilibrium is reached, when the spring force on the diaphragm is equal to the opposing force of the gas in the low pressure chamber.

In a single-stage regulator, delivery pressure increases as cylinder pressure falls, because there is less gas pressure exerted on the diaphragm. Thus, frequent adjustment of the control knob is required to maintain a constant delivery pressure. Therefore a two-stage regulator is recommended for applications requiring constant outlet pressure.

With the two stage regulator the point of use pressure stays practically constant, irrespectively of the cylinder pressure which sinks progressively as the cylinder empties.

Dual-Stage Regulators

A dual-stage regulator functions like two single-stage regulators connected in line. The first stage reduces the inlet pressure to a preset intermediate pressure. By adjusting the control knob the second stage reduces the intermediate pressure to the desired delivery pressure.

Like the single-stage regulator, outlet pressure from the first stage of the two-stage regulator rises as cylinder pressure decreases. However, the second-stage of the dual-stage regulator regulates, according to the preset level entered with the control knob, the point of use pressure as desired. Thus, delivery pressure remains constant even as the cylinder pressure lowers, eliminating the need for frequent control knob adjustment needed for a single-stage regulator.

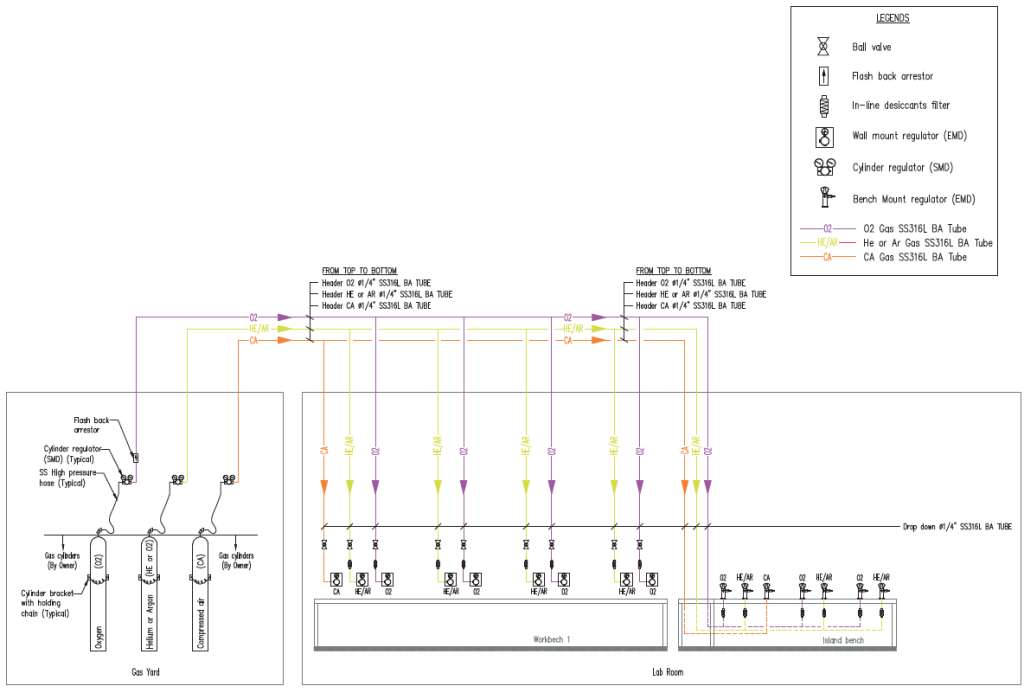

Central Gas Supply

- Gas panel SMD,

- Gas manifold BMD,

- Point/of/use regulator EMD,

- Point-of-use shut- off,

- Room shut-off,

- Floor shut-off

- Central shut-off

- Gas management,

- Line regulator

Gas Type | Purity (degress) | Purity | Max. Contamination (ppm) |

Pure gas | 2.5 | 99.5 % | 5000 |

| 3.0 | 99.9 % | 1000 |

High purity gas | 3.5 | 99.95 % | 500 |

| 4.0 | 99.99 % | 100 |

| 4.5 | 99.995 % | 50 |

| 5.0 | 99.999 % | 10 |

| 5.5 | 99.9995 % | 5 |

| 6.0 | 99.9999 % | 1.0 |

Ultra pure gas | 7.0 | 99.99999 % | 0.1 |

Schematic Drawing

Fittings

Advance Lab offers a comprehensive range of high-quality fittings designed to meet the stringent requirements of cleanroom and laboratory environments. Crafted from durable stainless steel, these fittings ensure superior corrosion resistance, longevity, and hygiene, making them ideal for applications in pharmaceuticals, biotechnology, healthcare, and electronics industries.

The product range includes a variety of components such as elbows, tees, reducers, and clamps, all engineered to provide seamless integration and leak-proof connections. With a focus on precision and compliance with international standards, Advance Lab fittings contribute to maintaining a contamination-free environment, supporting critical operations with reliability and efficiency.

Gas Alarm

Advance Lab’s Gas Alarm system is a cutting-edge solution designed to provide real-time monitoring and early detection of hazardous gas leaks in laboratory and industrial settings. Engineered to enhance workplace safety, the system ensures compliance with stringent safety regulations in industries such as pharmaceuticals, healthcare, biotechnology, and chemical processing.

Featuring highly sensitive sensors, the gas alarm offers accurate detection of various gases, including toxic, flammable, and inert gases. It is equipped with audible and visual alerts to promptly notify personnel of potential dangers, enabling quick response and risk mitigation. The system supports integration with existing safety infrastructure and offers user-friendly controls for seamless operation. With its reliable performance and robust construction, Advance Lab’s Gas Alarm is an essential safety solution for any facility handling hazardous gases.

Sign up today for update products and latest news for you

Join our mailing list!