MODULAR OPERATING THEATRES (MOT)

Modular Operating Theatre (SHD-MOT) Panel System offers flexibility, versatility, reliability and creativity in every aspect of its implementation. Advancelab partners with SHD ITALIA to provide healthcare clients with an internationally recognised & proven MOT solution with local expertise in project management, coordination and maintenance.

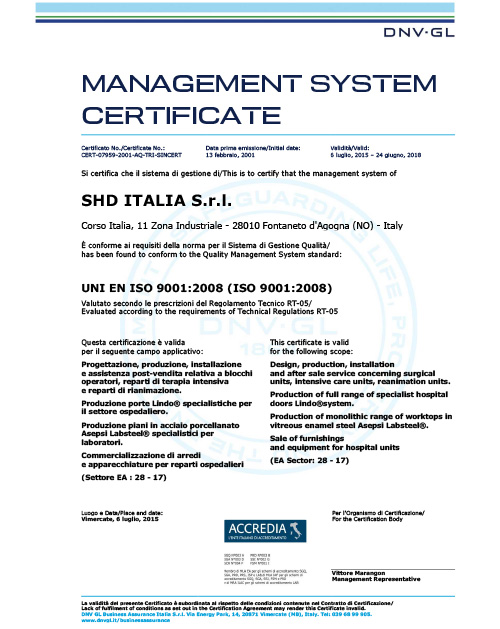

For almost 30 years SHD ITALIA designs, manufactures, markets and installs, in Italy and abroad, prefabricated operating rooms, intensive care units, dialysis units and central sterile services departments. With the expertise & experience of SHD ITALIA in new construction projects or hospital and clinic refurbishments around the world and together with a skilled design team, SHD ITALIA constantly develops and improves its products in order to achieve better, innovative and high quality solutions.

The self-loading wall cladding modular systems ensure an optimal and flexible performance of all critical hospital departments requiring controlled bacterial contamination. Consisting of a strong internal substructure and finished with individual and independent panels, it offers architects, medical planners and hospital operators an innovative and efficient way in setting up operating theatres (OT). Clean, quick and hassle-free installations & modifications can be done in a fraction of time compared to conventional systems, resulting in reduced downtime during modernization exercises and revenue losses. with air-tight doors, windows & ceilings, gas & electrical modules, touchscreen control panels and laminar flows, the SHD-MOT system can be easily integrated with OT equipment’s and accesories that contribute to a fully functional & effective operating theatre.

AIR FLOW & ENVIRONMENTAL CONTROLS

Operating rooms require stringent air and environment controls to promote a hygienic and sterile environment while ensuring surgeons and nurses are comfortable while carrying out the surgery. OR’s that fail to meet the standard requirements could lead to the patient suffering an infection during the operation.

Advancelab implements engineering controls and solutions that are able to ensure the air cleanliness and environments remain at optimum levels for the surgery. Together with HALTON, a Finnish company renowned as a global leader in environment solutions, we can create an operating room for you that offers flexible use and allows you to utilise the whole room.

The Halton Vita OR Space is an airflow solution which provides the highest required air cleanliness for the ultraclean operations in the entire operating space. This unique controlled-dilution innovation provides hygienic conditions and safety without compromising on comfort and freedom to use the whole room. It is also highly energy-efficient leading to reduced energy consumption and much quieter than many systems currently on the market. This dilution mixing ventilation solution creates a comfortable work environment, with very low risk of draughts. The Halton Vita Space 5 system is designed to provide ultraclean operating environment for high-risk operations. The air flow for each operating room is designed based on maximal microbial load e.g. maximum number of personnel and the quality of clothing system to be used in the room.

DfMA BED HEAD PANELS & UNITS

Power supply & medical gases are critical requirements that support the recovery of patients. Often located on Bed Head Units close to the patient, these outlets provide power to critical equipment’s and supply medical grade oxygen gas to the patient. However, their installation is often a challenge. With so many technical coordination’s required on site during the implementation phase, it could lead to mistakes and oversights being made that result in the delay of the project and additional cost.

Advancelab designs Bed Head Panels (BHP) that offers a quick, easy and safe method in addressing these issues. Our BHP’s are designed and fabricated off-site fully equipped with Bed Head Units (BHU) and the required gas pipings, conduits and trunkings. These fully assembled BHP’s are transported to site and installed as single unit with quick-connect fittings to the buildings mechanical & electrical infrastructure. This method reduces multiple coordination’s and time spent on site while being able to address design and installation concerns off-site.

Our partnership with MZ Liberec from the Czech Republic for the Bed Head Unit (BHU) piece, we are able to offer BHP’s using BHU’s in the traditional horizontal or vertical forms.

The Bed Head Units (BHU) are designed and fabricated by MZ Liberec, a leader in the manufacturing of medical and technical gas distribution systems since 1957. With its production facility in Rudnik, MZ Liberec is the largest company in the Czech Republic in its specialization in terms of number of employees and annual turnover. In addition to deliveries and installations in the Czech Republic, MZ Liberec, as also supplies to major healthcare facilities in more than 60 countries around the world.

Sign up today for update products and latest news for you

Join our mailing list!